1095

Nov 16-2023

The design and installation of warehouse rack require consideration of multiple factors. Here are some tips for design and installation:

1. Analysis of goods characteristics: Before designing the warehouse shelves, it is necessary to conduct an analysis of the characteristics of the goods to be stored, including size, weight, shape, and storage method. This information will help determine the structure and load capacity of the shelves.

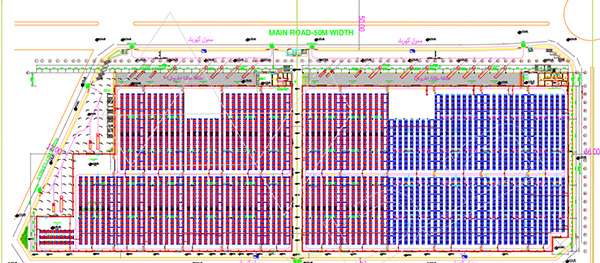

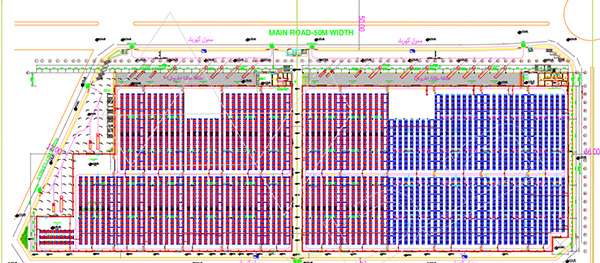

2. Planning of warehouse space: When designing the shelves, it is necessary to fully consider the spatial layout and utilization efficiency of the warehouse. Based on the size and shape of the warehouse, reasonable planning of the layout and arrangement of the shelves can ensure maximum utilization of the warehouse space.

3. Design of shelf structure: The design of the shelf structure needs to consider the weight and size of the goods, as well as the use needs of the warehouse. Choose the appropriate type of shelves, such as heavy-duty shelves, medium-duty shelves, light-duty shelves, etc. At the same time, the shelf structure should have sufficient stability and load capacity to ensure the safe storage of goods.

4. Safety considerations: In the design and installation of shelves, safety is a crucial factor. Ensure that the shelf structure is stable and that the connecting parts are reliable. Consider the fire resistance performance of the shelves, select flame-retardant materials, and set up fire extinguishing equipment. At the same time, set up safety signs and evacuation channels for the shelves in case of emergency evacuation.

5. Installation techniques: During the installation process of the shelves, it is necessary to follow relevant installation specifications and requirements. Ensure the verticality and levelness of the shelves and use appropriate tools and equipment for installation. During installation, rigorous quality control and inspection need to be carried out to ensure the installation quality of the shelves.

6. Regular inspection and maintenance: After installation, regular inspection and maintenance of the shelves are necessary. Check whether there are any loose or damaged parts in the structure and connecting parts of the shelves, and repair or replace them in a timely manner. At the same time, regularly clean the shelves and goods to ensure cleanliness and safety of the shelves.

In summary, designing and installing warehouse shelves requires consideration of goods characteristics, warehouse space planning, shelf structure design, safety considerations, installation techniques, and regular inspection and maintenance. Through reasonable design and installation, the service life and safety of the shelves can be improved, and the storage efficiency of the warehouse can be increased.

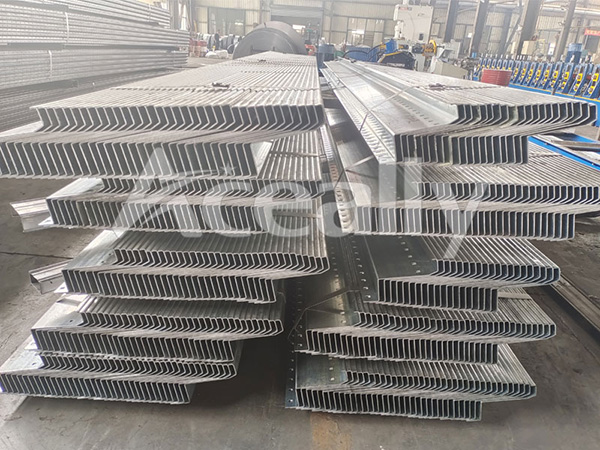

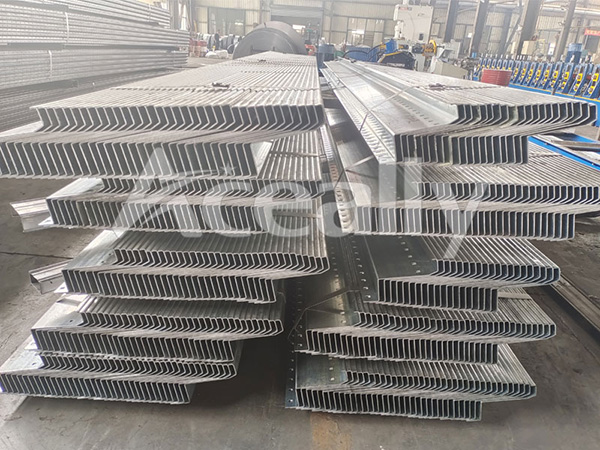

Aceally company has been specializing in the design and installation of shelf storage systems for over 20 years, with an excellent design team that offers various types of shelves to help save space and operate more efficiently. Our shuttle radio storage rack system features a leading domestic guide rail production line that ensures quality and production efficiency.

Prev

Next

+86 13959222269

+86 13959222269 [email protected]

[email protected]

+86 13959222269

+86 13959222269 [email protected]

[email protected]